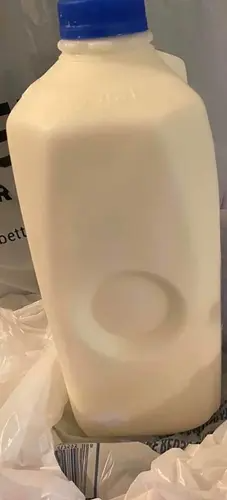

We all pour milk from those familiar plastic jugs every morning, but have you ever stopped to notice that small circular dent on the side? It’s more than a quirk — it’s an engineering marvel that keeps your milk safe, your jug sturdy, and your fridge clean.

The Real Purpose of the Circular Dent

The indentation on your milk jug isn’t just a design flourish — it’s a pressure control feature that keeps milk fresh and the jug intact.

1. Acts as a Pressure Release System

Milk naturally expands and contracts with temperature changes:

- When cold, milk and air inside the jug contract.

- When warm, they expand.

Without that dent, the jug could bulge or even burst. The indentation provides a flexible space that expands or contracts as needed to maintain balance and prevent leaks.

2. Prevents the Jug from Collapsing

The dent also reinforces the jug’s structure — like a built-in shock absorber. It:

- Distributes pressure evenly

- Prevents the walls from buckling

- Allows lighter, more sustainable materials

Pro tip: When you press the dent and feel it pop, that’s intentional flexibility — not weakness!

The Evolution of the Milk Jug Design

Before plastic, milk came in glass bottles — heavy, fragile, and expensive. In the 1950s and 60s, manufacturers adopted HDPE (high-density polyethylene), a lighter and safer alternative.

However, early plastic jugs had problems:

- They expanded too easily when milk warmed.

- They buckled under pressure during transport.

- They sometimes leaked or split open.

Engineers solved this by introducing the circular dent — a simple tweak that allowed the jug to flex without breaking. This innovation made it possible to stack, ship, and store milk safely while reducing material use.

The Science Behind the Dent

Milk jugs are made using a process called blow molding, where molten plastic is inflated inside a mold. During this process, designers add the dent to help manage internal stress and pressure changes.

- Absorbs expansion: when milk warms up and pressure rises

- Contracts safely: when the jug cools, avoiding vacuum collapse

- Adds rigidity: the curved dome shape reinforces strength

In simple terms, the dent allows the jug to breathe without breaking — a perfect blend of science and practicality.

Why the Dent Pops In or Out

Ever notice how the dent changes shape? That’s the jug’s pressure control mechanism at work:

- When cold, the dent pulls inward.

- When warm, it pushes outward.

This design prevents the jug from bulging or collapsing — the same principle that keeps soda bottles intact, only safer and smarter.

The Dent’s Hidden Role in Transportation and Sustainability

The circular dent isn’t just about temperature. It also plays a vital role in transportation efficiency and environmental sustainability.

- Prevents cracks and leaks during shipping

- Allows lighter, thinner plastic to be used safely

- Improves recyclability and reduces waste

Modern milk jugs weigh about 60 grams — nearly half their weight from 30 years ago — thanks to this design innovation. That’s millions of tons of plastic saved each year!

Beyond Milk: Other Products Use It Too

Once you notice it, you’ll start spotting similar dents on:

- Juice jugs

- Cooking oil bottles

- Cleaning products

In all these cases, the principle is the same — pressure regulation, structural integrity, and material efficiency.

Everyday Engineering Brilliance

Bonus Fact: The Dent as a Freshness Indicator

Here’s a hidden bonus: that circular dent can also serve as a spoilage warning.

If the dent bulges outward dramatically, it may signal that the milk has spoiled or that bacteria inside are producing gas — a clear visual cue to toss it out safely.

Final Thoughts

That tiny circular dent on your milk jug does far more than meet the eye. It:

- Balances internal pressure

- Strengthens the jug

- Prevents spills and leaks

- Supports sustainability

- Even signals spoilage

Next time you pour a glass of milk, take a moment to appreciate that small dent — a testament to innovation, engineering, and the brilliance of everyday design.